In modern industrial production, induction heating equipment has become an important choice in the field of pipe billet heating due to its high efficiency, energy saving, and environmental protection characteristics. As a key link in metal hot processing technology, the heating of tube blank requires high equipment performance and process adaptability. Hebei Forever Electromechanical will provide you with a detailed introduction to several induction heating devices commonly used for heating pipe blanks, helping you choose the appropriate solution.

The power frequency steel pipe induction heating furnace uses a 50Hz mains frequency for direct heating and is suitable for heating steel pipe blanks with larger diameters.

The electromagnetic field penetration of power frequency equipment is strong, suitable for pipe blanks that require deep heating.

Due to mature technology, it is an economical and practical choice under specific conditions.

Commonly used in the preheating or overall heating process of heavy-duty industrial pipe blanks.

However, it should be noted that power frequency equipment has relatively low power density and high energy consumption, making it suitable for application scenarios with relatively relaxed accuracy requirements.

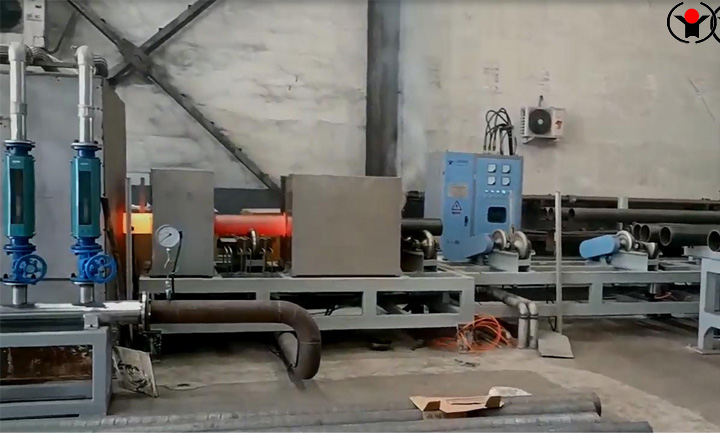

The working frequency of intermediate frequency induction heating equipment is usually between 200 Hz and 10 kHz, and it is a widely used type of equipment in tube heating.

By changing the operating frequency, different heating depths can be adjusted to meet the requirements of different specifications and materials of pipe blanks.

Intermediate frequency steel pipe induction heating equipment combines high power density and energy efficiency, making it suitable for rapid heating processes.

Easy to connect with automated production lines and achieve full process intelligent control.

Common application scenarios include surface or overall heating of small and medium-sized steel pipes, as well as preheating before forging.

The operating frequency of high-frequency induction heating equipment is usually above 10 kHz, suitable for surface heating of thin-walled tube blanks.

High frequency equipment can quickly heat the surface of the tube blank to the appropriate temperature, reducing heat loss.

Suitable for scenarios with high requirements for surface hardening, local heating, and other processes.

Surface heating is only targeted at the target area, further improving heating efficiency.

Due to its high frequency, it is suitable for surface hardening treatment or local heat treatment of thinner pipe blanks in a short period of time.

The dual frequency induction heating device combines the characteristics of mid frequency and high frequency, and can achieve the combination of deep heating and surface heating.

It can simultaneously meet the needs of overall heating and local fine heating of the pipe blank.

Complete multiple heat treatment objectives in one heating process to improve production efficiency.

Dual frequency equipment is widely used in the heat treatment process of high-performance alloy steel pipes and is an ideal choice for multi-purpose production lines.

In the design of the heating scheme for the billet, the selection of suitable induction heating equipment should take into account the following factors:

Is it surface heating, overall heating, or local heating?

The size and material of the pipe blank will directly affect the selection of equipment.

Determine equipment power, frequency, and automation level based on production line requirements.

Stability and long-term usage costs are essential factors that cannot be ignored.

Through a comprehensive analysis of power frequency induction heating equipment, medium frequency induction heating equipment, high-frequency induction heating equipment, and dual frequency induction heating equipment, you can choose steel pipe induction heating machine that meets the process requirements according to your own needs. In the design of customized equipment solutions, the combination of good equipment and scientific heat treatment processes will significantly improve production line efficiency and product quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-20-2025