Hebei YUANTUO medium frequency bar material heat treatment production line is a non-standard

Induction heating equipment, which is mainly designed and manufactured for quenching and tempering heat treatment of steel bars. It can meet the heat treatment of round steel, steel bars, bar materials and long shafts of various specifications, and replace the old well furnace, trolley furnace, box resistance furnace and other heat treatment furnace, It is also the mainstream equipment for bar quenching, tempering and heating.

Main parameters of bar medium frequency heat treatment production line:

1. The materials are 35, 35CrMo, 40, 40CrMo, 42CrMo, 45, etc

2. Diameter of steel bar: 20 ~ 250 mm; Length: 2 ~ 12m

3. Heating power supply power: 100-8000kw

4. Heating efficiency: 0.5t/h — 30t / h 30t / h

30t / h

Design of bar medium frequency heat treatment production line:

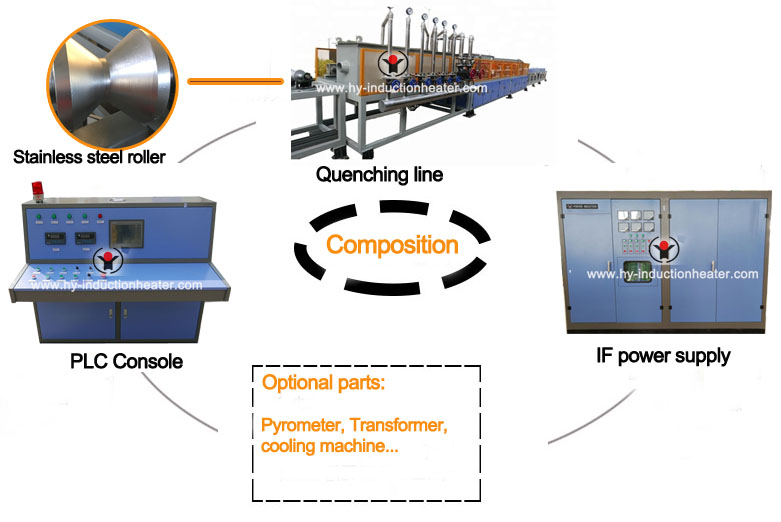

1. The roller table in front of the furnace and between the furnace bodies designed for quenching and tempering treatment electric furnace: made of 304 non-magnetic stainless steel, inclined and cooled with water, which greatly prolongs the service life of the roller table.

2. Spray system: multistage stainless steel spray ring is adopted, and the pressure and flow of the spray ring are adjusted independently to meet the requirements of different hardenability.

3. The control system adopts PLC automatic intelligent control system with high production efficiency.

4. The American Leitai two-color thermometer is used to detect the temperature, display the workpiece temperature in real time and heat evenly.

Characteristics of bar medium frequency heat treatment produce line :

1. Controlled by medium frequency power supply, all digital, high power,

2. Fast heating speed and less oxidation decarbonization.

3. With careful design and high degree of automation, it can realize full-automatic operation. It can realize full-automatic operation by selecting automatic feeding and automatic discharge sorting device and equipped with PLC control system.

4. Uniform heating, high temperature control accuracy, easy to realize the requirements of uniform heating and small core surface temperature difference. The temperature control system can accurately control the temperature.

5. Variable frequency motor is adopted, each shaft motor is driven by reducer, controlled by independent frequency converter, and the running speed is controlled by sections, so that the blank can move forward at a uniform speed, heat evenly and quench evenly.

6. The induction furnace body of long steel bar heat treatment production line is easy to replace. Induction furnace bodies of different specifications are configured according to different workpiece sizes. Each furnace body is designed with water and electricity quick change joints, so that the furnace body can be replaced easily, quickly and conveniently within 3 minutes.

7. American Leitai thermometer is used to control the temperature of steel rod and display it in real time.

8. After quenching and tempering heat treatment, the steel bar of the medium frequency heat treatment production line has high plasticity and strong toughness, does not need to be straightened, and meets the national standards.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 08-06-2021