The Pipe induction annealing heat treatment furnace has significant technical advantages in the field of steel pipe heat treatment. Its process characteristics are mainly reflected in high efficiency, energy saving, precise temperature control, high degree of automation, and strong adaptability.

(1) Efficient and energy-saving

Induction heating principle: By generating eddy current heating directly on the surface of the steel pipe through electromagnetic induction, the thermal efficiency can reach 60%~80% (traditional gas stoves only 30%~40%), and energy consumption can be reduced by 20%~40%.

Rapid heating: The heating rate is fast (up to 100-200 ℃/s), shortening the process cycle and suitable for continuous production lines.

Partition temperature control: Multiple coils are independently controlled to achieve precise energy distribution in different temperature zones, avoiding ineffective heat loss.

(2) Accurate temperature control and uniformity

Closed loop temperature control: Infrared temperature measurement or real-time feedback from thermocouples, temperature control accuracy within ± 5 ℃, ensuring consistent annealing softening effect (such as carbon steel pipe hardness deviation ≤ 5HB).

Electromagnetic stirring effect: The induced magnetic field promotes the uniform distribution of heat inside the steel pipe, reduces the temperature difference between the inside and outside (≤ 15 ℃), and avoids the problems of “surface overburning and insufficient core” in traditional furnaces.

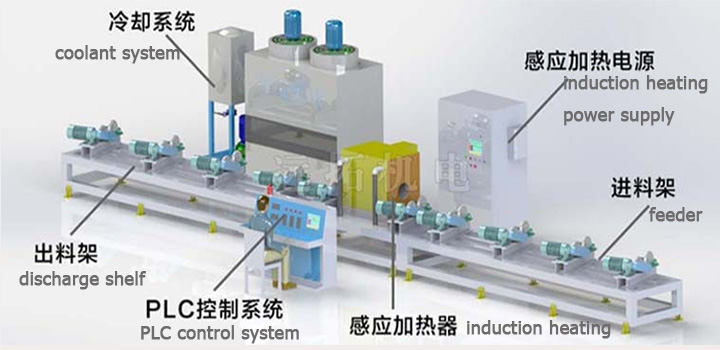

(3) Highly automated of steel tube pipe induction annealing machine

PLC/PC control system: programmable annealing curve (such as heating insulation cooling rate), storage of multiple sets of process parameters, and one click switching between different steel grades (such as 20 # steel and 304 stainless steel).

Intelligent diagnosis: automatic alarm for coil overload, abnormal cooling water and other faults, reducing human intervention.

(4) Process flexibility

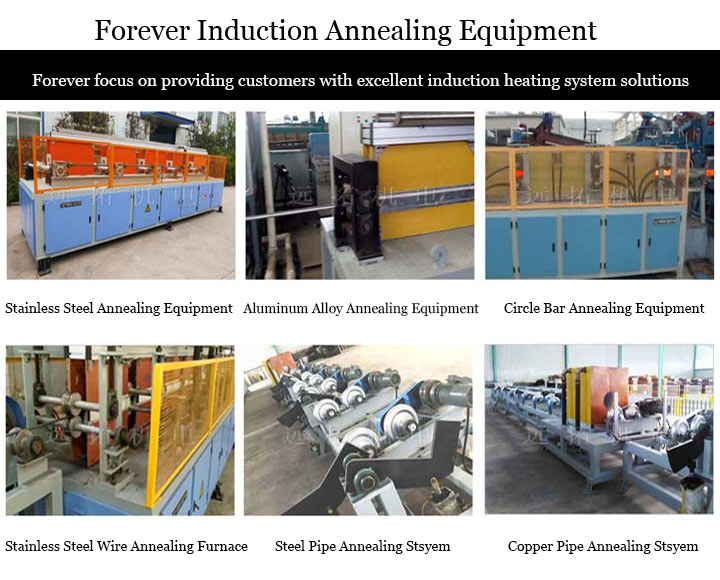

Wide range adaptability: It can handle steel pipes with diameters ranging from 10 to 500mm and wall thicknesses ranging from 1 to 30mm, including carbon steel, alloy steel, stainless steel, and other materials.

Diversified annealing requirements: Supports complete annealing, stress relief annealing, spheroidization annealing, etc., with a wide range of hardness adjustment (such as 150-250HB).

The Forever steel pipe induction annealing equipment significantly improves the uniformity and consistency of steel pipe annealing through efficient induction heating and intelligent control, especially suitable for high-end precision pipe processing. Its energy-saving features can help users reduce overall costs, while flexible process configurations can quickly respond to diverse production needs.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-27-2025