steel pipe induction annealing equipment

Features:

Workpiece diameter: medium 20~medium 500mm

Workpiece length: greater than 2m

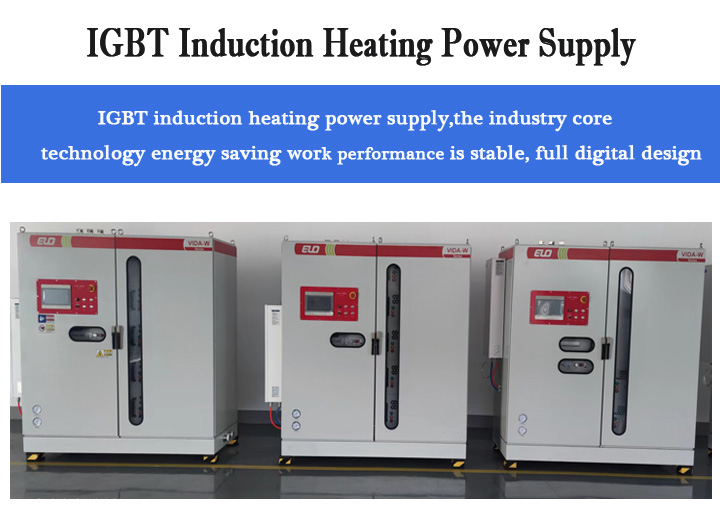

Equipment power: KGPS160KW~8000KW

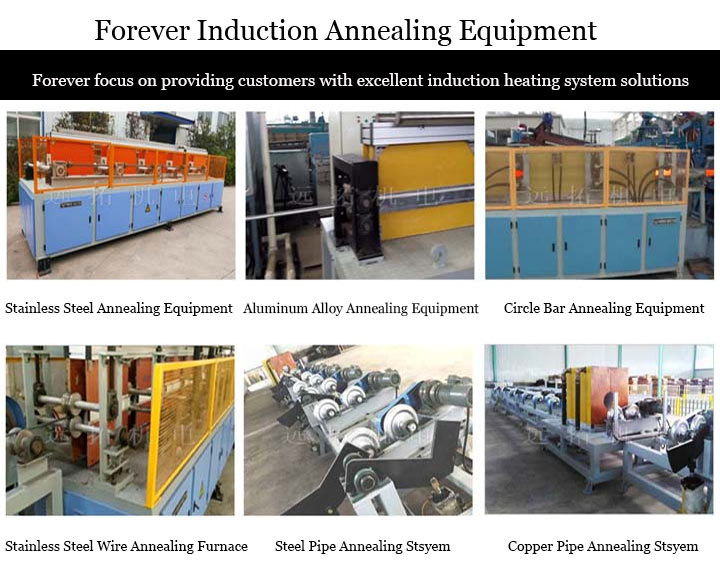

Applicable workpieces: metal pipes such as steel pipes, seamless pipes, thick walled steel pipes, etc.

Product Detail

Application Video

Product Tags

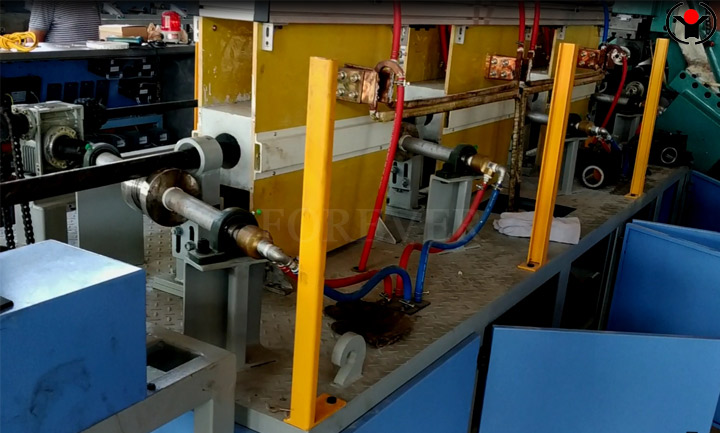

Steel pipe induction annealing equipment

The induction annealing production line for steel pipes is a new type of electric furnace for steel pipe annealing treatment in recent years, widely used in the annealing treatment industry of steel pipes, non dimensional pipes, thick walled steel pipes and other pipes. It has the advantages of uniform heating temperature, fast heating speed, high production efficiency, and less oxidation and burning loss. It is becoming increasingly popular in the steel pipe annealing heat treatment industry, and its application range is also becoming more and more popular. Welcome customers to visit and inspect our company.

Fast heating speed, uniform heating, less oxidation and decarbonization, simple operation, and high degree of automation

Workpiece diameter: medium 20~medium 500mm

Workpiece length: greater than 2m

Equipment power: KGPS160KW~8000KW

Applicable workpieces: metal pipes such as steel pipes, seamless pipes, thick walled steel pipes, etc.

Characteristics of Steel pipe induction annealing production line :

1. Compact structural design, low line loss, low energy consumption per unit output, and the advantages of high efficiency and energy conservation.

2. The degree of automation is high, which can achieve fully automated operations and reduce the labor intensity of workers.

3. Widely applicable, the transmission mechanism does not require improvement and can be used for heating various specifications of bar materials.

4. Easy to operate and maintain, employees can operate independently after simple training.

5. Fast heating speed, can be heated upon opening the furnace; Low oxidation decarbonization, burning loss rate<0.25%, saving materials.

6. Uniform heating, furnace temperature uniformity ≤ ± 10 ℃

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.