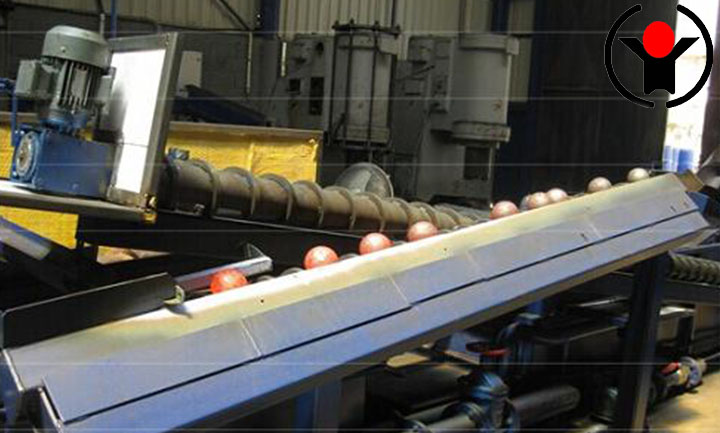

With the rapid development of round steel rolling technology and medium frequency furnace heating technology, the wear-resistant hot rolled steel ball production line developed by Forever Electromechanical Co., Ltd. stands out, making the automated production of wear-resistant steel balls a reality. The editor of Forever Electromechanical believes that this wear-resistant steel ball production equipment continuously heats round steel containing certain wear-resistant materials through a medium frequency heating furnace, and the round steel directly enters the rolling mill to roll out the required wear-resistant steel balls. This new process, new equipment, new materials, and new technology wear-resistant steel ball production equipment has the characteristics of high efficiency, energy conservation, and environmental protection, making wear-resistant steel ball production equipment of epoch-making significance.

The wear-resistant steel ball hot rolling equipment production line uses a medium frequency heating furnace for heating the round steel, using the principle of electromagnetic induction heating to heat the round steel in contact. The heat is generated within the round steel itself, so the wear-resistant steel ball production equipment has the following characteristics:

1. The wear-resistant steel ball rolling equipment production equipment has short heating time and high efficiency. The thermal efficiency of the medium frequency heating furnace can reach 60-70%, the heating efficiency of the flame furnace is only about 20%, and the heating efficiency of the resistance furnace is only about 40%;

2. The wear-resistant steel ball production equipment has a fast heating speed, which can double the productivity of the heating equipment and form a seamless continuous production line with subsequent heat treatment equipment;

3. When using medium frequency Induction heating equipment before hot forming, due to the fast heating speed and short heating time, the burning rate of oxide skin generated by the blank is very low;

4. The medium frequency heating furnace has reduced heat dissipation loss and greatly reduced workshop temperature, improving the working environment of the workshop. Additionally, induction heating does not produce smoke and dust, resulting in low noise and purifying the working environment of the workshop. Workers are no longer exposed to harmful physical health hazards such as heat radiation, high temperature, and noise, while establishing the company’s external image and development trends.

Forever Electromechanical has many years of production experience in the induction heating equipment industry. Steel ball hot emulsion equipment is sold to over countries and regions both domestically and internationally, and the production process is mature. If you have any needs in this regard, you can visit the company for inspection and visit, or contact the technical personnel in the station by phone or WeChat to provide you with a detailed quotation plan for steel ball hot rolling heating equipment for free.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 09-04-2023