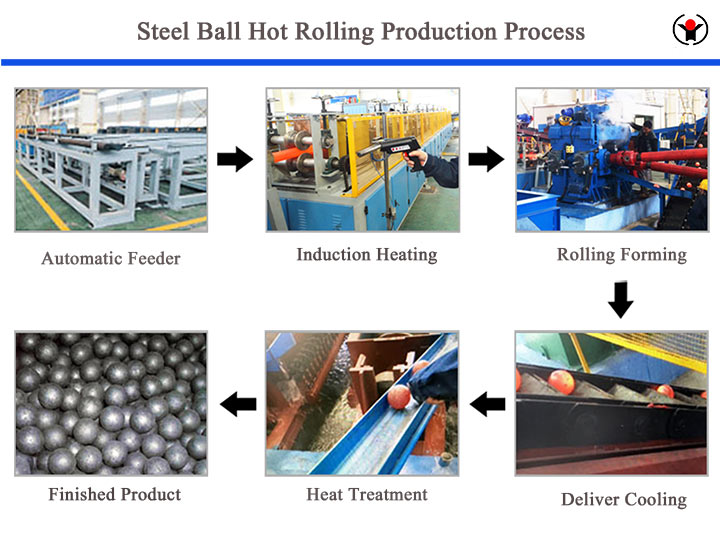

The Forever Grinding steel ball hot rolling production line has the following characteristics:

Automated production: The grinding steel ball production line adopts an automated control system, which sets and monitors parameters through a touch screen interface, greatly simplifying the production process.

Efficient production: With strong production capacity, it can roll steel balls with a diameter of 30mm to 80mm with high precision, and the produced steel balls have exquisite appearance, high hardness, and low damage rate.

Energy saving and environmental protection: Using electromagnetic induction principle for heating, compared with traditional gas furnaces, coal-fired furnaces and other heating equipment, the heating is more uniform, and the surface of the billet does not produce oxide skin or burn damage, with high automation production capacity and energy saving and environmental protection.

High precision control: The production line is equipped with infrared thermometers and PLC control systems, which can automatically control the heating temperature and production efficiency, ensuring isothermal rolling during the rolling process.

Stable and efficient: The production line adopts a cast steel semi closed frame with good rigidity, easy and fast replacement of guide plates, and high efficiency, ensuring stable, efficient, and high-quality operation of the production line.

Intelligent management: The production line is equipped with Siemens PLC control system and touch screen display, which can achieve real-time temperature display and parameter recording functions, improve production efficiency and yield.

These characteristics make the Forever steel ball production line have significant advantages in improving production efficiency, ensuring product quality, reducing labor costs, and energy conservation and environmental protection.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-16-2025