The round steel heating steel ball production line is a new type of manufacturing technology. Forever Electromechanical Equipment Manufacturing Co., Ltd.’s round steel heating steel ball production line has a breakthrough process and gradually replaces the casting ball. Hebei Forever Electromechanical is a professional steel ball hot rolling equipment manufacturer.

Rolling steel balls is a new type of rolling technology with many advantages. So what is the process of hot-rolling steel balls?

1. After inspection, the round steel rod is cut to a suitable hot rolled length according to the specified length.

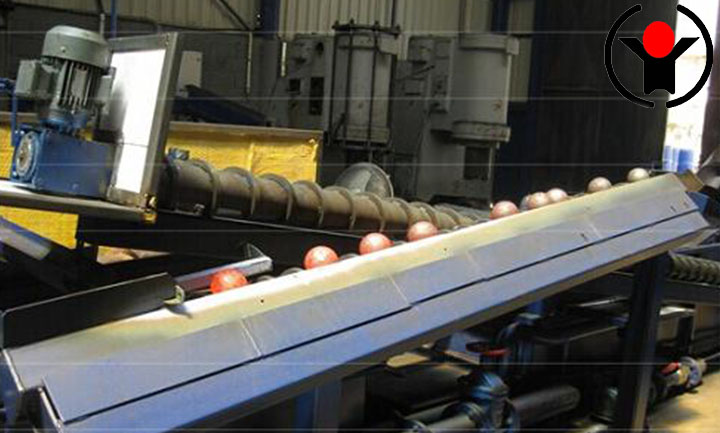

2. The steel bar is rolled to the appropriate temperature before heating in a continuous furnace.

3. The steel in the red billet state is also fed into the oblique rolling mill, where it is rotated by a special spiral groove roller between the two and continuously rolled into a rigid ball. Each ball mill can roll 60 to 360 balls per minute.

4. After entering the factory’s specially designed online quenching tempering heat treatment, the heat treatment induction heating equipment makes the steel ball have high and uniform hardness, and immediately enters the red state of the steel ball.

5. After the qualified products are delivered to the finished product warehouse.

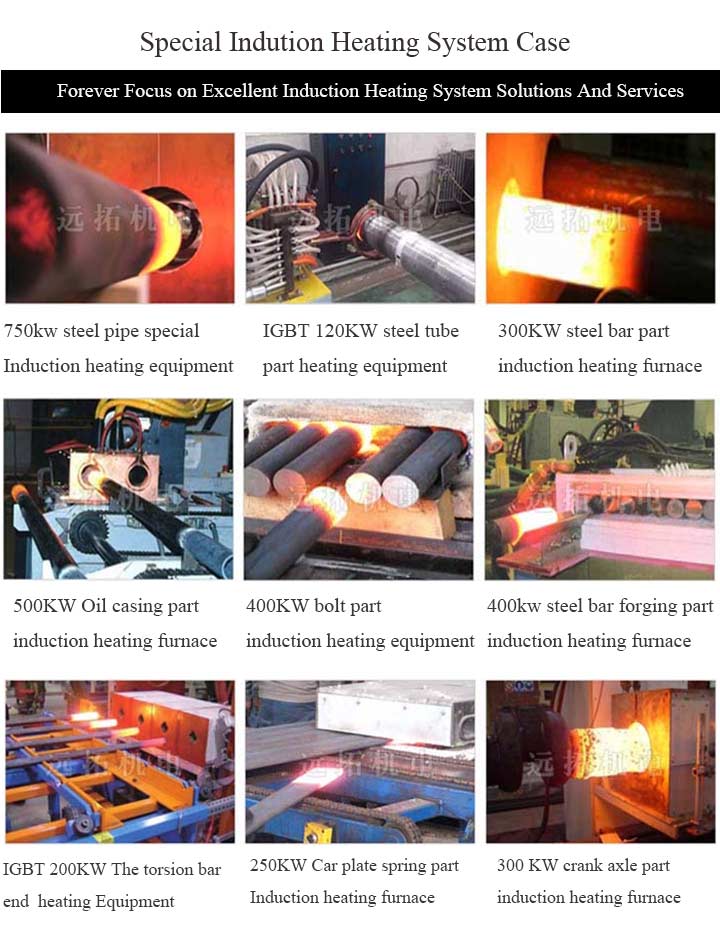

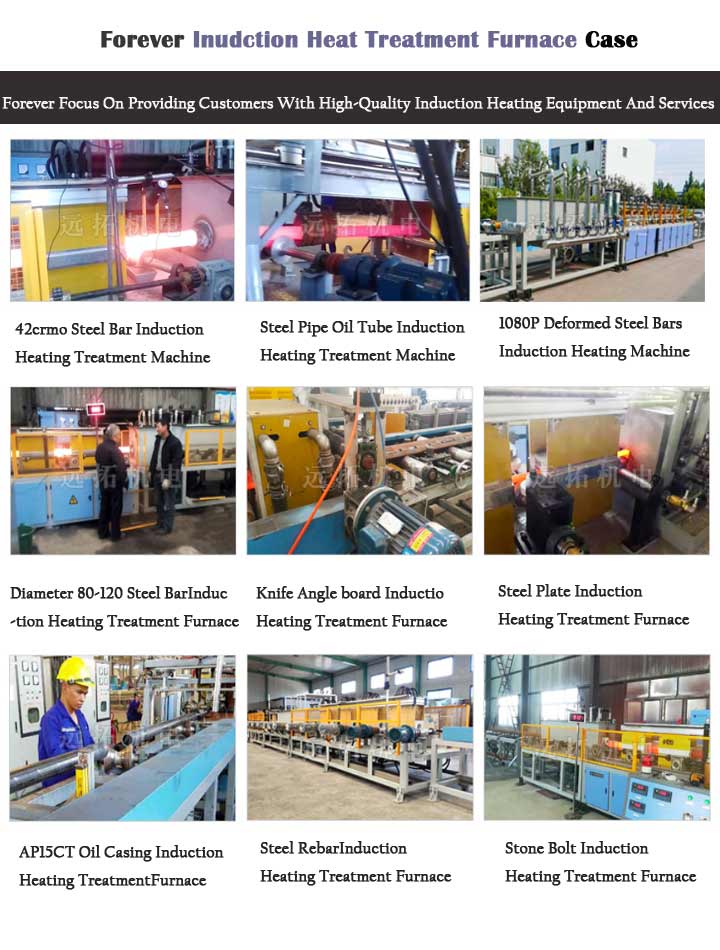

The steel ball hot rolling furnace has the following characteristics:

1. Hot rolled steel balls have all the advantages of steel, and after heat treatment, high-quality steel balls are produced.

2. The round steel heating steel ball production line has high efficiency, large output, mechanized rolling ball production, high degree of automation, no need for manual production, and adopts fewer and fewer human factors.

3. Stable quality, high hardness, good hardenability, dense structure, small grain size, small deformation, uniform and non deformed steel balls, good wear resistance, impact toughness up to 12-35j/cm2, and crushing rate less than 1%;

4. Low energy consumption, pollution-free, low labor intensity, and low production costs.

5. Good formability, small geometric tolerance, stable quality, low wear rate, long service life. It is an existing bundled iron ball and graded forged steel ball with 2-5 times, and the price is reasonable.

6. Ball hardness can reach 60-67 HRC, with poor internal and external balance hardness

7. The impact toughness can reach 1235j/cm3.

8. Specific weight (7.8-7.85 J/cm3).

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-09-2023