The progress of science and technology and the development of society are changing our mode of production. In this era of fierce competition, the requirements for the heat treatment equipment market are getting higher and higher. Hebei FOREVER Electromechanical Induction Hardening Equipment adopts advanced IGBT module, which greatly improves the speed of steel bar hardening heat treatment, improves the production efficiency of users, and induction hardening process makes production more energy-saving. From the market point of view, from the production demand of enterprises, steel bar hardening furnace has great development potential.

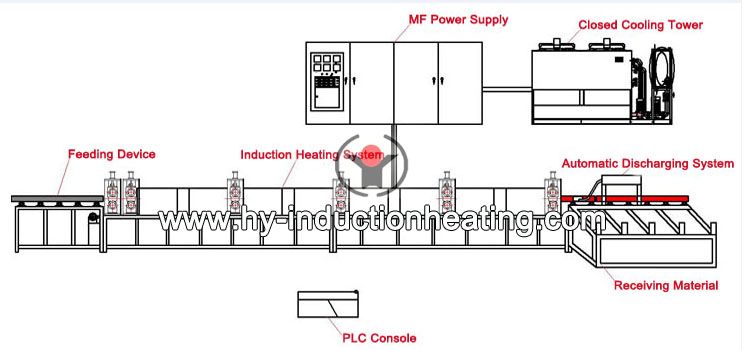

Hebei FOREVER has been engaged in the development of medium frequency hardening furnace for nearly 20 years. The round steel bar hardening and heat treatment production line adopts a 12 pulse feeding line, with automatic feeding, automatic heating, automatic spray cooling, automatic unloading, and temperature division function. Here we will tell you the basic configuration of the steel bar hardening furnace.

1. Medium frequency induction resonant power supply

Series medium frequency power supply, full touch screen control, pure digital tuning, high power output, fast heating, energy conservation and environmental protection. We have nearly 20 years of experience in the induction heat treatment industry.

2. Induction heating equipment

The induction coil is designed according to the size and heating speed of the user’s workpiece; Induction brass has become a unified design, designed by engineers with years of experience in Hebei Yuantuo Electromechanical Co., Ltd., which is easy to control and has good thermal insulation performance. The outside of the furnace is protected by 8-10mm yellow plate, which is more durable.

3. Spray system

The spray system adopts multi-stage spray cooling, and the pressure and flow between the spray rings at all levels are adjustable. Meet the requirements of different permeability.

4. PLC control system

PLC man-machine interface, the operation interface is very simple, fully digital, and the parameter depth is adjustable. The corresponding language switch can be provided according to different countries and regions, and the production date can be restored by one button.

Hebei FOREVER Electromechanical Equipment Manufacturing Co., Ltd. mainly researches, develops, produces and sells various series of complete sets of induction heating equipment, with complete models and very stable product quality. The company has a number of induction heating technical engineers, nearly 20 years of experience in research, development and production of induction heating technology and induction heat treatment equipment, and has problems related to induction heating. Find professional technical engineers to solve them!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 10-24-2022