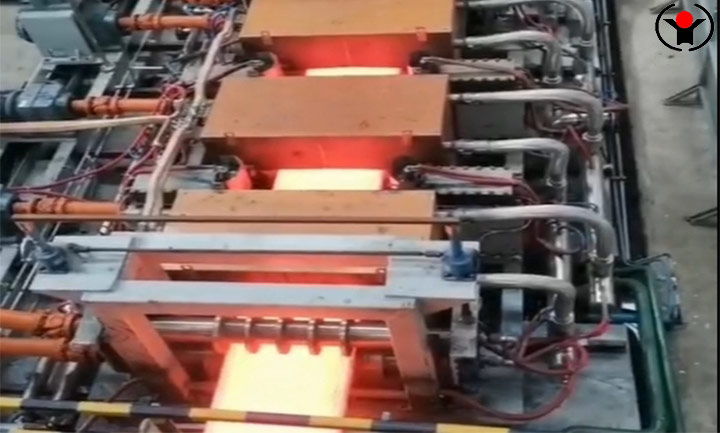

Steel slab heat treatment for hot formed

1. Principle of Induction Heating

Induction heating utilizes the principle of electromagnetic induction to generate eddy currents inside the steel plate through alternating current, thereby rapidly heating it up. The main advantages include:

Fast heating: The heating rate is much faster than traditional furnace heating (such as gas furnaces).

Local heating: It can accurately control the heating area and reduce the heat affected zone.

Energy saving and environmental protection: high thermal efficiency, no combustion exhaust emissions.

Automation compatibility: easy to integrate into production lines, achieving temperature closed-loop control.

2. Application in Forging

Purpose: Heat the steel plate to the plastic deformation temperature (usually 1100 ° C~1250 ° C) for subsequent forging and forming.

Advantages:

Reduce the generation of oxide scale (compared to gas stoves) and improve material utilization efficiency.

Avoid overburning or decarburization to ensure the internal quality of forgings.

Suitable for medium to high frequency induction heating (1-10 kHz), with moderate penetration depth and uniform heating.

Typical applications: Heating before forging gear blanks, shaft components, flanges, etc.

3. Application in Hot Forming

Purpose: Heat the steel plate to the austenitizing temperature (approximately 900 ° C~950 ° C), then rapidly press and form it and quench it (such as high-strength steel parts for automobiles).

Advantages of Steel slab heat treatment furnace:

Precise temperature control: Ensure complete austenitization of the material, followed by quenching to obtain martensitic structure (ultra-high strength).

High production efficiency: Short heating time (in seconds), suitable for assembly line operations.

Energy saving: More than 30% more energy-efficient than traditional heating furnaces.

Typical applications: Hot stamping forming for automotive A/B pillars, collision beams, etc.

4. Comparison of key parameters

Parameter forging heating hot forming heating

Target temperature 1100 ° C~1250 ° C 900 ° C~950 ° C

Frequency selection: Intermediate frequency (1-10 kHz), High frequency (10-100 kHz)

Heating time from minutes to seconds to tens of seconds

Subsequent processes include forging, forming, stamping, and mold quenching

5. Precautions

Material adaptability: Heating parameters need to be adjusted according to the composition of the steel plate (such as carbon content).

Temperature uniformity: Complex shaped workpieces require the design of multiple coils or mobile sensors.

Cooling control: Hot forming requires the use of a mold water cooling system to achieve quenching effect.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 06-09-2025