What is the principle of Induction heating machine process?

We know that in order to obtain high performance and high quality metal workpiece, it is necessary to carry out heat treatment processing, change the surface structure of metal steel, improve its strength, hardness, bending strength, service life, and so on.

Metal heat treatment is a process method of heating metal workpiece in a certain medium to a suitable temperature, and then cooling it at different speeds after holding it at this temperature for a certain time. Metal heat treatment is to endow or improve the working performance of the workpiece by changing the microstructure inside the workpiece or changing the chemical composition of the workpiece surface. Its characteristic is to improve the internal quality of the workpiece, which is generally not visible to the naked eye.

Quenching and tempering are closely related and often used together. In order to obtain certain strength and toughness, the process of combining quenching and high temperature tempering is called quenching and tempering. After some alloys are quenched to form supersaturated solid solutions, they are kept at room temperature or a slightly higher appropriate temperature for a long time to improve the hardness, strength or electrical magnetism of the alloys.

Heat treatment refers to heating the material to a certain temperature, holding it for a certain time, and cooling it to room temperature or lower at a certain rate, so as to improve the structure of the material and obtain materials with excellent performance. It generally refers to the treatment of metal materials, especially “steel”.

Such heat treatment process is called aging treatment. The method of combining pressure processing deformation and heat treatment effectively and closely to make the workpiece obtain good strength and toughness is called thermomechanical treatment; The heat treatment in the negative pressure atmosphere or vacuum is called vacuum heat treatment. It can not only make the workpiece not oxidized, not decarburized, keep the surface of the workpiece smooth and clean after treatment, improve the performance of the workpiece, but also conduct chemical heat treatment by penetrating agent.

The heat treatment method of high temperature tempering after quenching is called quenching and tempering treatment. High temperature tempering refers to tempering between 500-650 ℃. Quenching and tempering can greatly adjust the properties and materials of steel. Its strength, plasticity and toughness are good, and it has good comprehensive mechanical properties. Tempered sorbite is obtained after quenching and tempering.

The above is sorted out by Forever electromechanical induction heating equipment manufacturer. For more information about heat treatment and induction heating equipment, please pay attention to Forever electromechanical customer service hotline. Professional technical engineers can customize the heat treatment process and technical scheme for you.

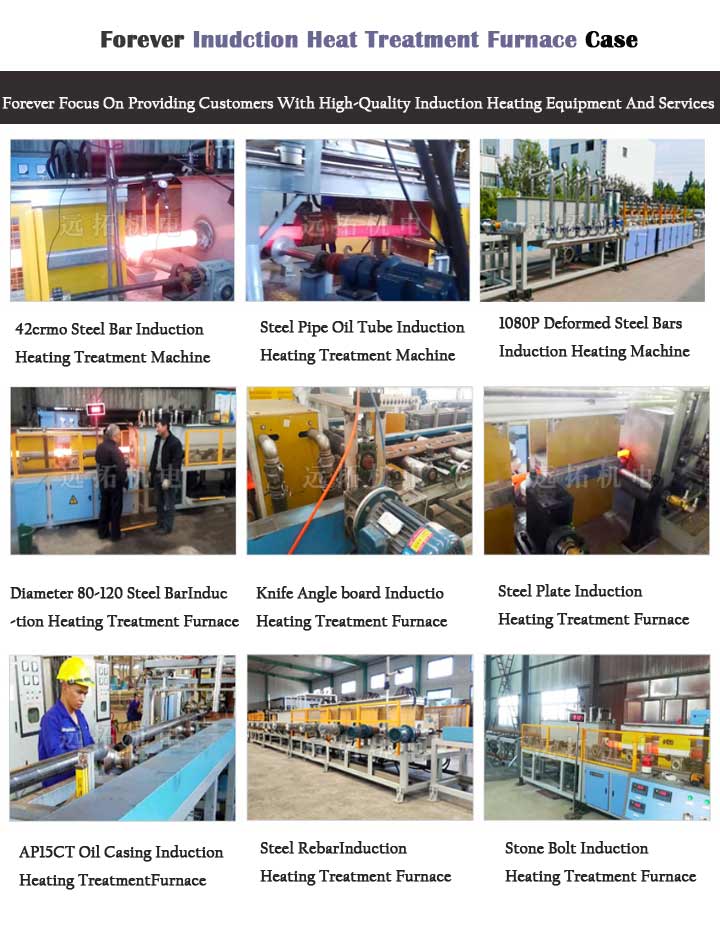

Our company also has other machines: steel bar hardening and tempering production line 、Steel ball induction forging furnace 、steel tube induction preheating furnace 、medium frequency furnace 、steel billet induction reheating furnace 、metal heating forging furnace 、square billet heating furnace and so on.

Welcome to call to inquire about the furnaces details.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 01-23-2023