Medium frequency heating power supply is an efficient electrical energy conversion device used in industrial scenarios such as metal heating, melting, heat transfer, quenching, etc. Its power can reach hundreds of kilowatts to megawatts. The following is a detailed introduction to its key features, composition, and application areas:

1、 Core Features

High power output

The power range typically ranges from several hundred kilowatts to several megawatts, suitable for large-scale industrial applications.

High efficiency (up to 90% or more), significant energy-saving effect.

Frequency range

Intermediate frequency (1kHz-20kHz), balancing penetration depth and heating speed, suitable for different metal materials such as steel, copper, and aluminum.

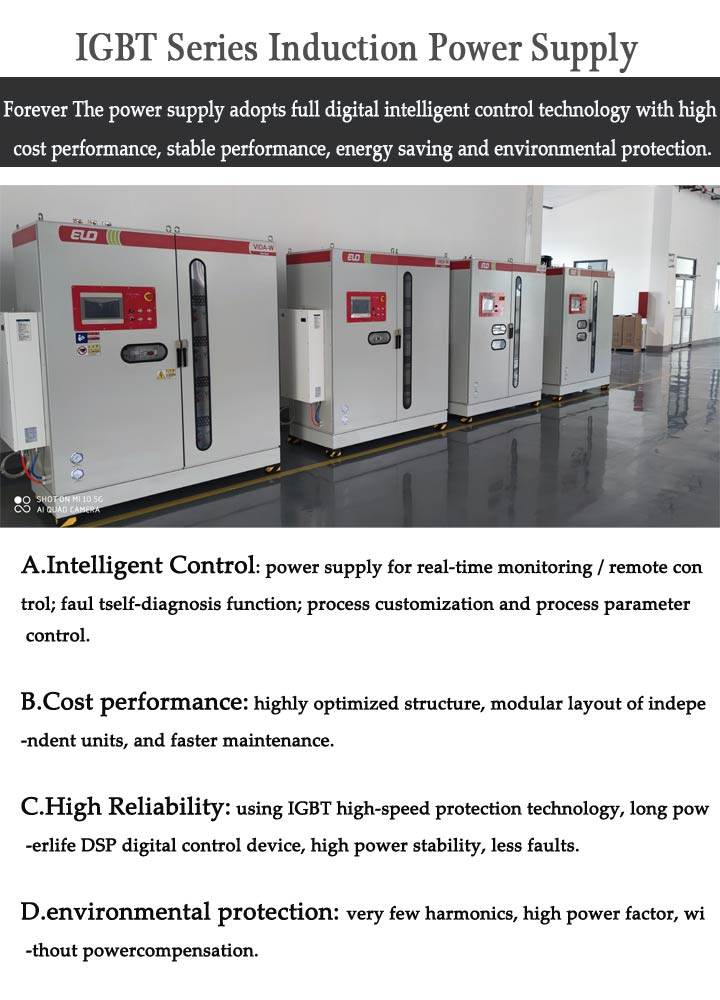

Precise control

By using modern power devices such as IGBT or MOSFET, combined with digital control (such as PLC or DSP), precise adjustment of temperature, power, and frequency can be achieved.

strong stability

Equipped with overcurrent, overvoltage, and overheating protection functions, suitable for long-term continuous operation in industrial environments.

2、 Main components

rectifying unit

Convert three-phase AC power to DC power, commonly using thyristors or diodes for rectification.

inverter unit

Invert DC power into medium frequency AC power through IGBT module, with adjustable frequency.

resonant circuit

LC resonance is composed of induction coils and compensation capacitors to improve energy transmission efficiency.

control system

Using PID algorithm or adaptive control to adjust output parameters in real-time and match load changes.

Cooling system

Water or air cooling design ensures heat dissipation requirements under high power.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-22-2025