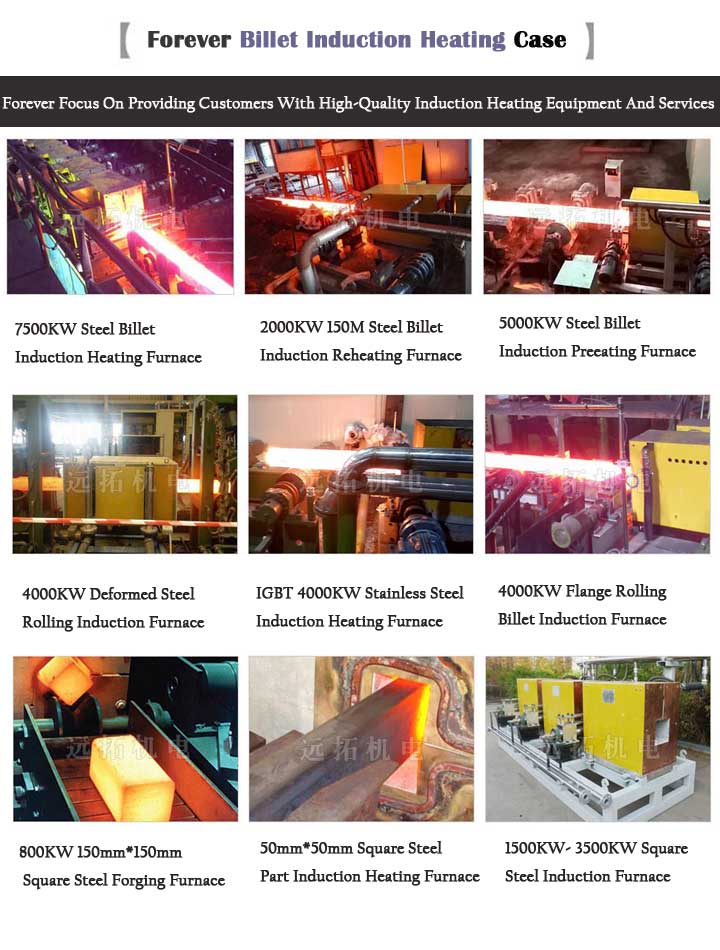

Forever (assuming brand name) square billet induction heating machine is a rapid heating device used for metal square billets (such as steel billets, aluminum billets, etc.) before rolling, forging, or heat treatment. It uses the principle of electromagnetic induction to achieve efficient and accurate heating.

1、 Core points

Efficient electromagnetic induction heating

Using a medium to high frequency power supply (500Hz~10kHz), the interior of the metal is directly heated through eddy current effect, with a thermal efficiency of 60%~75%, much higher than that of a gas furnace (30%~40%).

Fast heating speed (completed in minutes), suitable for continuous rolling or high-frequency production needs.

Accurate temperature control

Infrared temperature measurement+PLC closed-loop control, temperature accuracy ± 10 ℃, avoiding overburning or uneven heating.

Multiple coil independent temperature control to meet the heating needs of different parts of the billet (such as end reheating).

Automation and Intelligence of Square billet heating furnace

The integrated automatic feeding, conveying, and discharging system can be interlocked with the rolling mill and robotic arm to achieve unmanned operation throughout the entire process.

Intelligent diagnostic system: Real time monitoring of equipment status, predicting faults (such as coil overheating, power supply abnormalities).

energy conservation and environmental protection

Zero combustion emissions, no CO ₂, NOx and other pollutants, in line with low-carbon production requirements.

Oxidation loss<0.5% (gas furnace up to 1%~3%), reducing metal waste.

Modular design

The power supply, induction coil, and cooling system are modular, easy to maintain, and support quick replacement or upgrade.

Core advantages of square steel billet induction heating furnace

Specific manifestations of advantages

1. The energy efficiency ratio is 30% to 50% lower than the comprehensive energy consumption of gas stoves, and the long-term cost advantage is significant.

2. Good heating uniformity is achieved through multi-stage coil zone temperature control, with a temperature difference of ≤ 20 ℃ between the core and surface of the billet (traditional heating methods can reach a temperature difference of over 50 ℃).

3. Strong adaptability to handle various materials such as carbon steel, alloy steel, copper, aluminum, etc., with a billet cross-sectional range of 50mm × 50mm~300mm × 300mm.

4. Strong stability water cooling system+high-temperature resistant materials (such as ceramic rollers), supporting 24-hour continuous operation.

5. Environmentally compliant with no emissions of waste gas or wastewater, easily meeting environmental standards such as ISO 14001.

6. Intelligent management supports remote monitoring, data recording (heating curve, energy consumption analysis), and assists in the construction of digital factories.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-30-2025