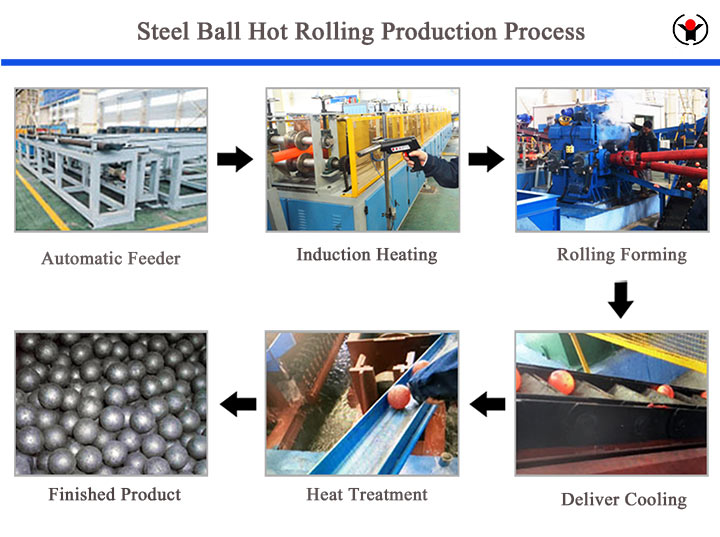

The Forever Grinding steel ball hot rolling heating furnace is an automated hot rolling equipment used for efficient production of wear-resistant steel balls (grinding balls), widely used in the manufacturing of ball mill grinding media in industries such as mining, cement, power, metallurgy, etc. This production line achieves high-precision and large-scale production of steel balls through hot rolling technology, with characteristics such as high efficiency, low energy consumption, and high wear resistance.

The Forever Grinding steel ball hot rolling production line adopts a medium frequency induction heating furnace as the core heating equipment. Compared with traditional gas furnaces, resistance furnaces, or coal-fired heating methods, it has the following significant advantages:

1. Efficient and energy-saving, reducing production costs

Fast heating speed: The medium frequency induction furnace can heat steel bars to rolling temperature (1000-1200 ℃) within 30-60 seconds, which is 3-5 times faster than gas furnaces. Reduce oxide scale and increase yield by 2-3%.

Low energy consumption: The electric thermal conversion efficiency is ≥ 85%, which is more than 30% energy-saving than gas stoves (40-50%). The electricity consumption per ton of steel ball is about 300-350kWh, with a lower overall cost.

Accurate temperature control: PLC+infrared temperature measurement, temperature fluctuation ≤ ± 10 ℃, to avoid overheating or insufficient heating.

2. High degree of automation, improving production efficiency

Fully automatic feeding: linked with the rolling mill to achieve continuous heating rolling without manual intervention.

Intelligent power adjustment: automatically matching heating parameters based on the diameter of the steel rod (such as differential heating between Φ 30mm and Φ 80mm steel rods)

Fault self diagnosis: Real time monitoring of coil and capacitor status, warning of potential problems, and reducing downtime.

3. Steel balls have better quality and improved wear resistance

Uniform organization: Induction heating has no “uneven heating and cooling” problem, sufficient austenitization, and more stable hardness after quenching (HRC 58-65).

Reduce cracks: Quickly heat to avoid coarse grains, and increase the impact toughness of steel balls by 10% -15%.

Surface smoothness: oxide skin thickness ≤ 0.1mm, reducing subsequent cleaning processes.

4. Strong adaptability to meet diverse needs

Compatible with multiple materials: low carbon steel (B2), medium carbon alloy steel (B3), and high chromium steel (such as Cr12) can all be heated.

Flexible adjustment of production capacity: The single line production capacity can reach 5-20 tons/hour, suitable for small and medium-sized or large-scale production.

Modular design: Customizable power (500kW-3000kW) and heating length (1-6 meters) according to customer needs.

Forever steel ball production line has become the preferred heating solution for modern grinding steel ball production due to its advantages of high efficiency, energy saving, intelligent temperature control, environmental protection, low-carbon, and high yield. It is particularly suitable for customers who have strict requirements for cost control, quality stability, and environmental compliance.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-27-2025