Induction heating furnace for T-steel, channel steel, angle steel

Features:

| Material | Carbon steel |

| Suitable for | 60*60-240*240 billet |

| Process | Induction heating for rolling |

Product Detail

Application Video

Product Tags

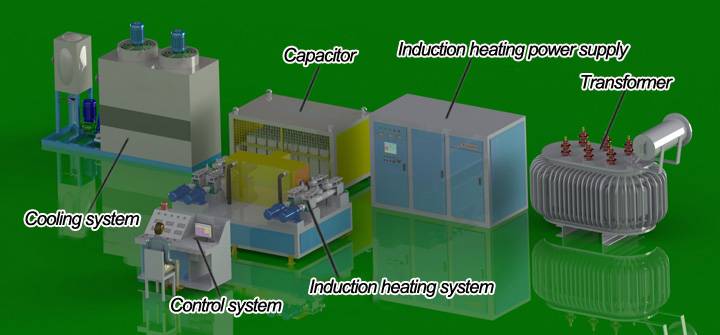

Forever is specialized in designing and manufacturing induction heating furnace for T-steel, channel steel, angle steel for more than 20 years, which consists of IF power supply, induction billet heater, remote console and transportation system.

Equipped with induction heating furnace for T-steel, channel steel, angle steel, we can also provide closed cooling machine, transformer, low voltage cabinet and so on according to user’s requirement.

The reference for Induction heating furnace for T-steel, channel steel, angle steel

| Product name | Induction heating furnace for T-steel, channel steel, angle steel |

| Brand | Forever |

| Material | Carbon steel |

| Suitable for | T-steel, channel steel,angle steel heating before processing |

| Heating way | Induction heating |

| Heating temperature | 1000-1200℃ |

| Power required | 100-8000KW |

Main features of induction heating furnace for T-steel, channel steel, angle steel:

1. High heating temperature, induction heating is a non-contact heating way, which will have low heat loss;

2. High heating efficiency -The heating speed is fast, the surface does not produce oxide scale;

3. Consistency of performance.

4. Easy to control the temperature – The product quality of the billet local heating device is stable and easy to worry about;

5. Can be heated locally – good product quality, energy saving;

6. Easy to achieve automatic control – save manpower and reduce labor intensity;

7. The working environment is good – the local heat treatment equipment for billet hardly generates heat, noise and dust;

8. Occupies less floor space – According to the user’s site rationalization equipment, the structure is compact;

9. Billet indcution heating furnace can heat complex workpieces and have a wide range of applications

10. The workpiece is easy to heat evenly – the product quality is good.

Intelligent induction heating power supply technology

The intelligent induction heating power supply technology adopts semiconductor inverter device that takes thyristor as the power switching element and converts three-phase industrial frequency AC power into single-phase intermediate-frequency power (200-10000 Hz). It is mainly used for induction heating and heat treatment of steel bars, billet inline induction heating, surface quenching and so on.The core of the device is the control system. The domestic control system has experienced the stages of discrete components, small scale integrated circuits, and CPLD logic digital circuits. Our factory invested large funds in the upgrading of control system. In the June of 2015, we launched the fourth generation intelligent control system which adopts DSP+FPGA mode to improve the response speed and control precision control; Using the most advanced large scale integrated circuit has further enhanced the stability and anti-interference ability of main panel; Through industrial touch screen and direct communication to the main control board control, the interface is more concise. Digital setting for all the parameters has completely solved the problems of the temperature drift brought by previous analog line potentiometer and strong randomness. After putting into the market, the effect is good and is well received by the customers.

The MCSV7.6F IF power control system consists of three parts: main control panel, rectification trigger panel and inverter trigger panel. Its key component adopts DSP + FPGA composites integrated circuit and fully digital circuit implementation. All parameters can be digitally corrected on the touch screen or remote device which has characteristics of high reliability, strong anti-interference ability and quick response. The device has complete phase sequence adaptive circuit, no need synchronous transformer, no need to adjust the synchronous resistance, phase adjustment and synchronization are eliminated in the debugging. As long as the electrical and electronic devices are not damaged and the electrical and electronic components are firmly connected, it can guarantee the direct start and quickly enter the working state.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.