Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. has strong technical strength and provides comprehensive services such as development, design, manufacturing, installation, commissioning, and maintenance of steel plate induction hardening production lines. It has a complete and scientific quality management system, advanced steel plate quenching heat treatment furnace production technology, and an advanced production team. The equipment has reliable quality, stable operation, and pollution-free production. Welcome to inquire by phone.

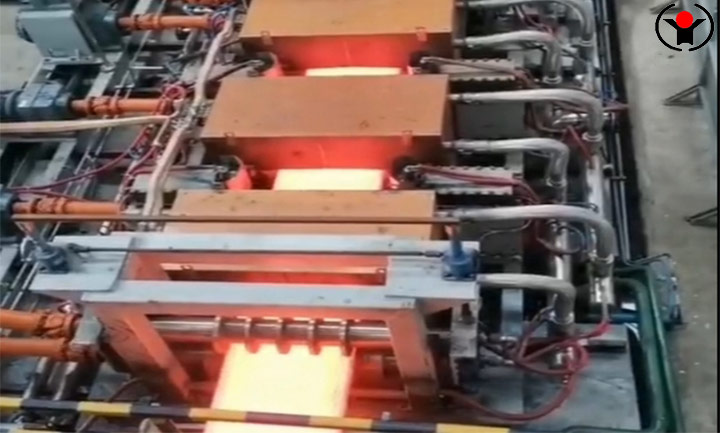

Basic principle: Place the workpiece in an inductor made of hollow copper tube, and apply medium or high frequency alternating current to form an induced current of the same frequency on the surface of the workpiece. The surface of the workpiece is rapidly heated (800-1000 degrees Celsius can be raised within a few seconds, and the core is still close to room temperature), and then immediately sprayed with water for cooling (or oil immersion quenching) to harden the surface layer of the workpiece.

Introduction to the configuration and working performance of the mechanical part of the steel plate induction hardening furnace:

1. Roller conveyor with dual pressure rollers, each axis driven by an independent motor reducer and controlled by an independent frequency converter, enables the steel plate to move forward flexibly and uniformly on the roller conveyor, ensuring uniform heating of the workpiece. The water-cooled roller variable frequency drive method is used for feeding, and the workpiece is transported at a constant speed. Induction devices are installed on the conveyor line to ensure smooth passage of the plate through the rollers.

2. The frame of the transmission mechanism has sufficient strength and rigidity. In order to facilitate equipment installation, adjustable feet are installed at the bottom of the frame to make the Steel plate induction hardening equipment more aesthetically pleasing as a whole.

3. According to the safety standardization requirements of the mechanical industry, all rotating exposed parts of machinery should be equipped with reliable protective devices, and the production line should comply with national environmental standards.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-19-2025