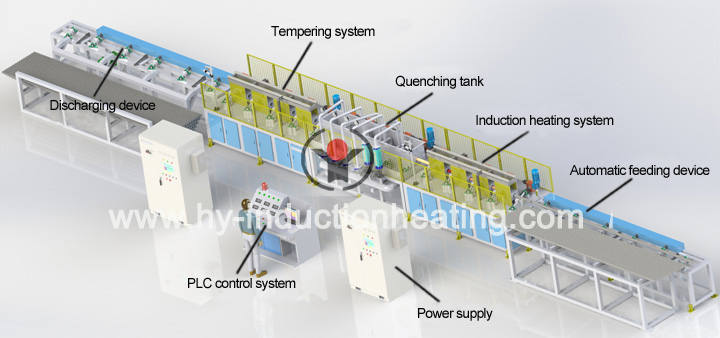

Oil casing induction heat treatment machine

Features:

| Steel grade |

J55,N80,L80,C90,T95,P110,Q125 |

| Casing diameter |

ø60.3-88.9 |

| Process | Quenching, tempering |

Product Detail

Application Video

Product Tags

Forever Oil casing induction heat treatment machine is special unit for casing heat treatment and water quenching.

The casing specification

| Item | Casing specification | Length/m | |

| Diameter/mm | Wall thickness/mm | 6-10 | |

| 1 | 60.3 | 4.83 | |

| 2 | 60.3 with upset | 4.83 | |

| 3 | 73 | 5.51 | |

| 4 | 73 with upset | 5.51 | |

| 5 | 88.9 | 6.45 | |

| 6 | 88.9 with upset | 6.45 | |

Steel grade: J55,N80,L80,C90,T95,P110,Q125

Standard: API Spec 5CT

The main technical parameters for Oil casing induction heat treatment machine

1.The way of charging and discharging: longitudinal feeding and transverse discharging.

2. Quenching medium: water;

3.Quenching method: outside spraying + internal spraying, rotary quenching;

4. Quenching capacity: 90% martensite after quenching

5.Temperature after quenching: less than 100 ℃;

6. Quenching uniformity: Sampling to do hardness test after quenching as per API. Sampling any part on the pipe, the hardness difference should be controlled in HRC3.0.

7.Straightness: End straightness is less than 2mm / m, full length is less than 0.002L

8. Mode of operation:Set automatic, manual and adjustment for the pipe heat treatment furnace; which is adjustable for equipment maintenance and commissioning;

9.Functions to achieve: picking material, feeding, retaining water, rotation, compression, outside spraying, inner spray,empty water.

Capacity requirement for heat treatment furnace for casing

| Item | Product name | Casing pipe Specification | Hourly capacity | |

| 1 | Outer diameter/mm | Length/m | PCS/Hour | |

| 2 | Casing with upset | ø60.3 | 6-10 | 25 |

| 3 | Casing with upset | ø73.02 | 25 | |

| 4 | Casing with upset | ø88.9 | 25 | |

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)