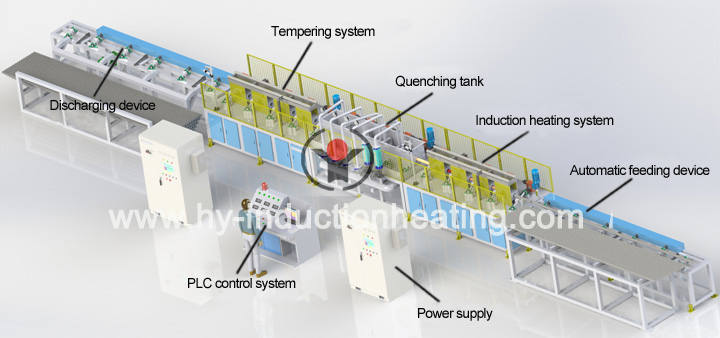

Bar quenching heat treatment furnace

Features:

| Material | 29Mn5, 25MnCr, 25CrMnMo |

| Bar diameter | ≥ø20mm |

| Process | Quenching, tempering, annealing |

Product Detail

Application Video

Product Tags

Bar quenching heat treatment furnace is manufactured by Forever, one factory located in China. Forever company has provided more than 500 sets of bar heat treatment furnace for different heat treatment industry,including round bar quenching furnace, plate quenching equipment, rod surface quenching equipment, shaft quenching furnace etc.

Site case for Bar quenching heat treatment furnace

| Product name | Bar quenching heat treatment furnace |

| Brand | Forever |

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

| Bar diameter | ≥ø20mm |

| Process | Quenching, tempering, annealing |

| Quenching temperature | 920-930℃ |

| Power required | 100-5000KW |

Inductor Parameter Design

According to the different parameters of the workpiece,our engineer will optimizatized design different inductor group to get the effect of high efficiency. The inductor for tempering will increase the inductor quantity and adding tempering holding box to get better structure after temepring,ensuring the workpiece performance meets the requirements.

Sprayer

it is a circular spray device made of stainless steel, installed in the discharge end of the inductor, the casing go through from the sprayer.The high-pressure cooling water from the spray hole wall will spray casing for cooling There is water collecting tank below sprayer and the cooling water flows into the quenching circulating pool through water collecting tank.

Why choose Forever Bar quenching heat treatment furnace ?

● Parallel resonant design, phase shift power, rectifier fully open, high power factor, small harmonic, simple operation.

● Power supply and induction heater always maintain the best match, full power output, saving 15-30% compared with the traditional inverter power.

● Frequency conversion adaptive, induction furnace replacement automatic matching without any artificial adjustments.

● Cabinet adopts T2 copper, sandblasting, passivation treatment; low leakage, anti-oxidation, effectively reduce line loss.

● Full touch screen control, pure digital setting, with a complete process records and strict level authority. The main parameters can be returned to the factory settings through one button..

● Bar heat treatment furnace has functions: over-current, over-voltage, water pressure, lack of phase, undervoltage, overload.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)