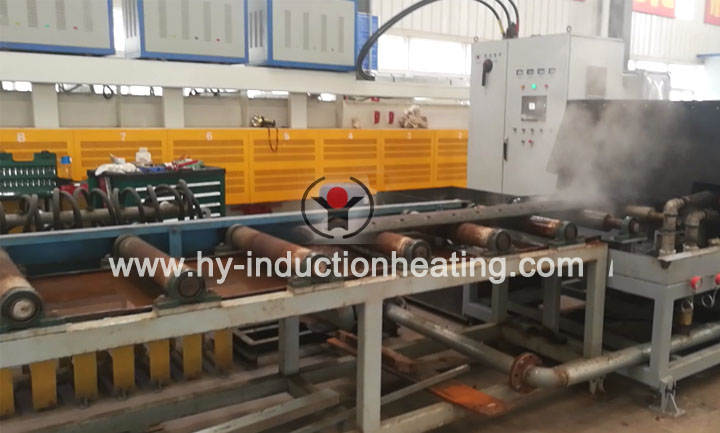

The Steel plate heat treatment furnace is suitable for medium frequency heat treatment of slab, steel plate, blade angle plate, engineering blade plate, etc. Roller conveyor+power double pinch roller, each axis is driven by an independent motor reducer and controlled by an independent frequency converter; Flexible design of differential output, segmented control of operating speed. We have designed a sturdy and durable track electrical isolation system to address the issue of workpiece and roller ignition damage

The Forever steel plate heat treatment equipment has the following advantages and characteristics:

Induction heating technology: using the principle of electromagnetic induction heating, the heating speed is fast and the efficiency is high. It can quickly reach the predetermined temperature of the steel plate, and the heating temperature is uniform, which can effectively control the hardening depth and surface quality of the steel plate.

Accurate temperature control: The steel plate induction heat treatment line is equipped with advanced temperature control modules that can monitor and adjust the heating power in real time, ensuring the uniformity of steel plate heating. It can also control the insulation time to avoid affecting the quenching and tempering effect due to overheating or uneven temperature distribution.

Automated control system: It realizes the automation of the steel plate heat treatment process. Operators only need to set core parameters such as heating temperature, insulation time, and cooling rate on the touch screen of the control panel. The Steel plate heat treatment furnace can automatically run according to the set program, reducing manual intervention and improving production efficiency and product quality stability.

Energy saving: Adopting network type energy-saving power control, IGBT based full bridge inverter circuit and other technologies, the power consumption is low. For example, the power consumption per ton of steel bar heat treatment quenching equipment after quenching is less than or equal to 500 degrees, far lower than resistance heating.

High reliability: The main control circuit of the equipment adopts an integrated modular design, which improves the service life of the equipment and facilitates maintenance; The protection function is complete, such as the steel bar heat treatment quenching equipment having overcurrent, overvoltage, water shortage, phase loss, undervoltage and other protection functions, which can ensure the safety and stability of the equipment during operation.

Wide applicability: Customized production can be carried out according to different specifications of steel plates and different heat treatment process requirements, suitable for the quenching and tempering needs of steel plate hardness, toughness, and surface quality in various industrial fields, such as automobile manufacturing, mechanical engineering, heavy equipment and other industries.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-08-2025