Pipe induction hardening and tempering machine

Features:

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

| Pipe diameter | ≥ø20 mm |

| Pipe length | ≥2000 mm |

| Process | Quenching, tempering |

Product Detail

Application Video

Product Tags

Forever hardening and tempering machine for pipe is non-standard customized products. The engineers will design the quenching and tempering furnace according to the parameters provided by the customers. Please provide detailed technical parameters such as pipe specifications, heating temperature, production efficiency, then we can give you the specific configuration for your project.

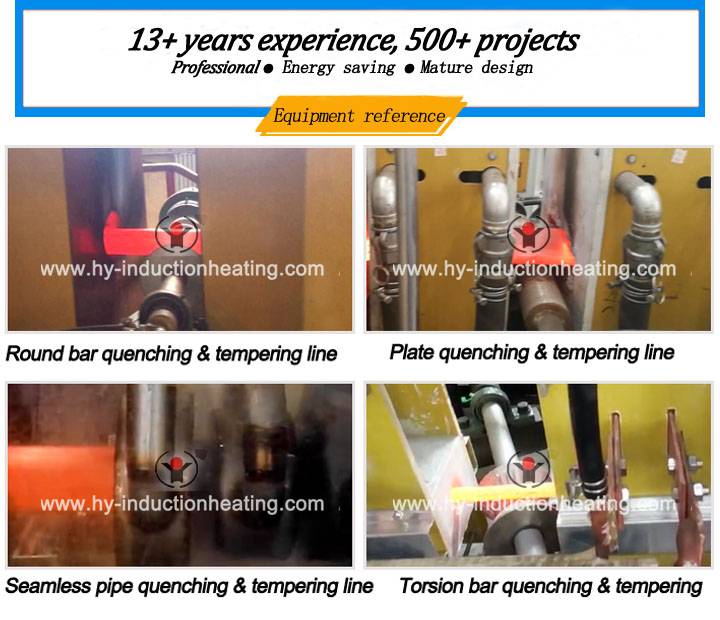

Site case for Hardening and tempering machine for pipe

| Product name | Hardening and tempering machine for pipe |

| Brand | Forever |

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

| Pipe diameter | ≥ø20 mm |

| Pipe length | ≥2000 mm |

| Process | Quenching, tempering |

| Quenching temperature | 920-930℃ |

| Tempering temperature | 680-700℃ |

| Power required | 100-5000KW |

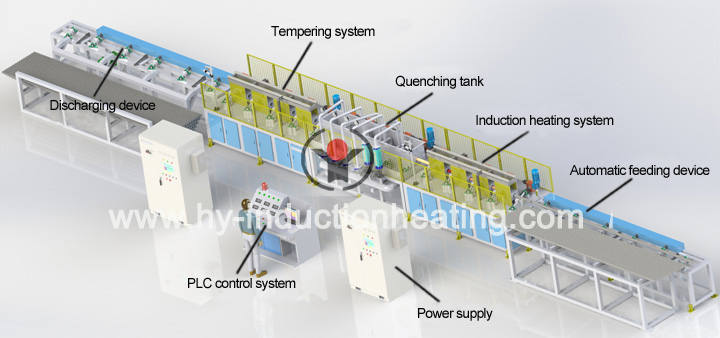

Hardening and tempering machine for pipe composition

● Feeding device

● Transportation roller table

● Induction heating system for quenching

● Spraying cooling system

● Induction heating system for tempering

● Automatic turning material device

● Water circulation system

● Electrical control system

Advantages for Hardening and tempering machine for pipe

1.Uniform heating: The angle between roller axis and bars axis is 18 ~ 21 °. The bars is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

2.Uniform cooling:To meet the requirements of different hardenability, spraying system adopts multi-level spray cooling and the pressure & flow in water spray ring at all levels is adjustable.The pipes will be placed in the middle of spray ring to ensure uniform pressure and flow. So the pipes needn’t straightening after heat treatment with our line. The surface hardness difference is very small, which is only HRC3.

3.Closed-loop temperature control system: Our engineer will set the process parameters in the system, and when the heating temperature is too high or too low, the system will adjust the temperature to the required temperature through adjusting power.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)