Medium frequency billet reheating furnace

Features:

| Material | Carbon steel |

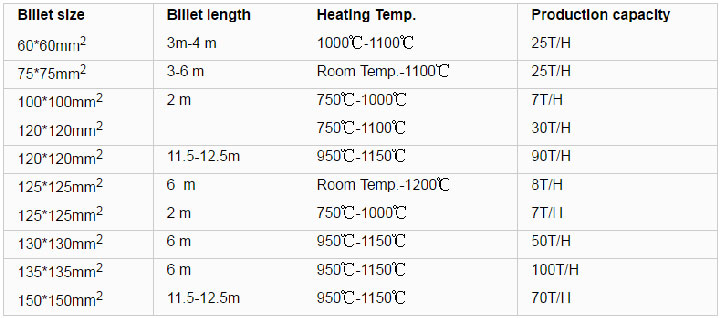

| Suitable for | 60*60-240*240 billet |

| Process | Induction heating for rolling |

Product Detail

Application Video

Product Tags

Forever Electromechanical provides customers with excellent solutions and quotations for induction billet heating furnace, and has more than 18 years experience and practice in the design, process, manufacture and management of induction billet heating furnace. Energy saving billet heating furnace full touch screen control, equipment high efficiency and energy saving, heating uniform, low power consumption and other characteristics

Inductive billet reheating furnace equipment adopts medium frequency power supply to control its characteristics:

1.20KHz broadband self-adaptive: a power supply for a variety of loads, load replacement without professional debugging, from intermediate frequency to ultra-audio frequency can achieve frequency self-adaptive.

2.Constant power output mode: the output power does not change with the workpiece temperature, high production efficiency, good product quality.

3.High starting success rate: constant power / constant voltage output mode to switch at any time.

4.Induction billet heating equipment has good anti-voltage fluctuation performance: voltage fluctuation range between 360-410V, does not affect product quality.

5.High reliability/low failure rate: synchronized with international power structure design and circuit design, comprehensive intelligent protection system, selection of internationally renowned brand components, signal fiber transmission, to avoid interference.

6.Intelligent fault diagnosis and on-line display fault treatment methods: more than 90% of the faults can be solved by the operator to improve production efficiency.

7.Operation status monitoring system: accurate, comprehensive, all-round display of power supply operation status, easy to formulate, modify processing technology.

8.Parameters on-line induction furnace billet heating equipment: device operation control, restriction protection and other parameters can be set online or remotely, set after power failure parameters do not lose.

Inductor shall be equipped with Energy saving billet heating furnace :

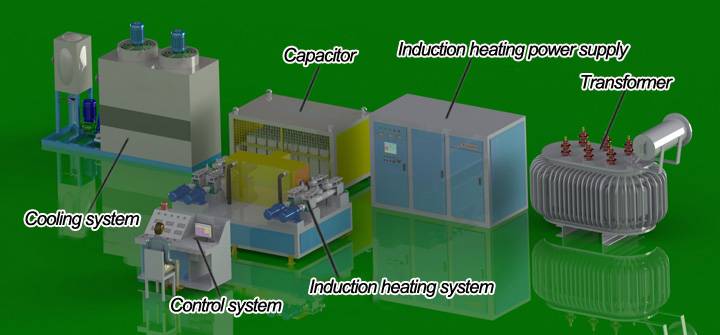

induction heating power supply PLC remote console, induction heater, capacitor cabinet, low voltage distribution cabinet, closed cooling tower, etc.

The furnace body of the furnace should be made of steel billet, the furnace body is designed by copying, the copper tube is wound with T2 oxygen free copper, the wall thickness of the copper pipe is greater than 2.5 mm, the insulation material of the furnace body is made of American imported knotting material, which has the advantages of high strength, high temperature resistance and longer service life. One water-cooled roller is installed between each furnace body and each roller is equipped with a variable-frequency speed regulating motor. The two ends of the furnace body package the whole plate of red copper. The furnace chassis frame is made of non-magnetic stainless steel or aluminum alloy to reduce the effect of magnetic flux leakage and heat on other devices. Water pressure gauge and water temperature protection are installed in each furnace. The temperature of the steel billet heating furnace is controlled by American Leytay thermometer, the heating is uniform, and the billet after heat treatment is free from overburning and crack. The heat permeability is good.

Inductance should be committed to the after-sales service of the billet heating furnace:

1, the company has a full-time after-sales service team, full-time personnel responsible for providing customers with high-quality services, after-sales service work has become institutionalized, programmed, Standardization.

2, the letter of the user service calls to set up the person to register, make reply on the same day.

3, the equipment problem that must deal with on the spot and the requirement to the user reach the scene within 24-48 hours, Ensure the quality of on-site service.

4, visit the relevant users regularly every year, deal with the problems in time, understand the users’ opinions and needs information.

5. For the newly invested induction furnace heating billet equipment, Call back every half a month to master product quality information in time.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.