Induction Annealing Machine For Steel Pipe

Features:

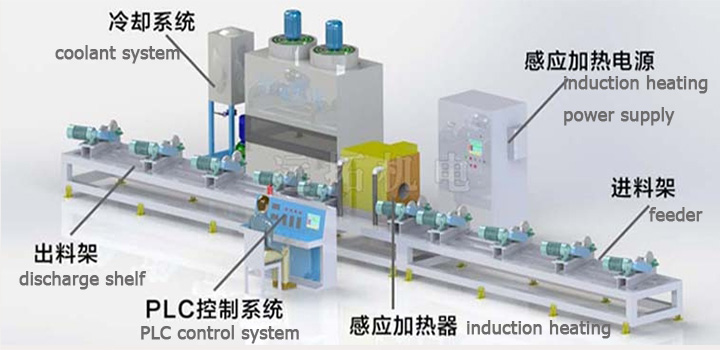

Product Name:Induction Steel Pipe Annealing Production Line

Workpiece Materials: Q195, Q235, 10, 20, 35, 45, 304316, 20C, 40Cr, 20CTIO, 35CIID, 42CrID, 40CrNI0, GCr15, 65 M, 50Mm.50Cr, 3Cr2w8V, 20CrhmTi, 5Crlmio, etc.

Product Detail

Application Video

Product Tags

Features:

Product Name: Induction annealing machine for steel pipe

Workpiece Materials: Q195, Q235, 10, 20, 35, 45, 304316, 20C, 40Cr, 20CTIO, 35CIID, 42CrID, 40CrNI0, GCr15, 65 M, 50Mm.50Cr, 3Cr2w8V, 20CrhmTi, 5Crlmio, etc.

Workpiece diameter range: diameter 20mm~406mm

Workpiece length range: greater than 2m

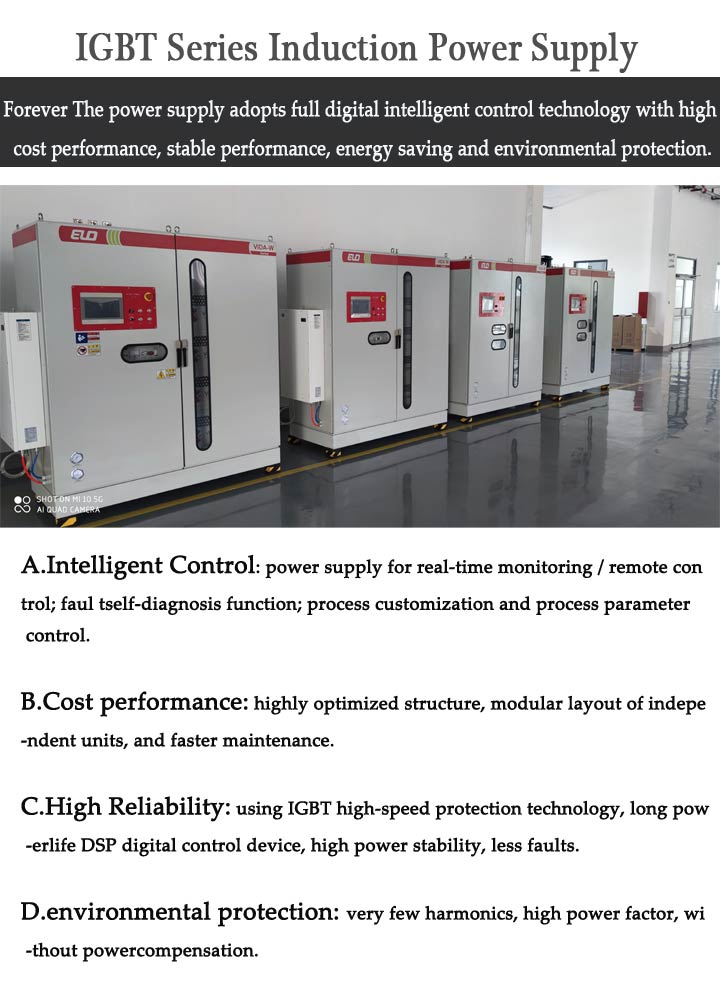

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Power consumption: calculated based on the customer’s workpiece material and diameter, heating temperature, operating speed, etc

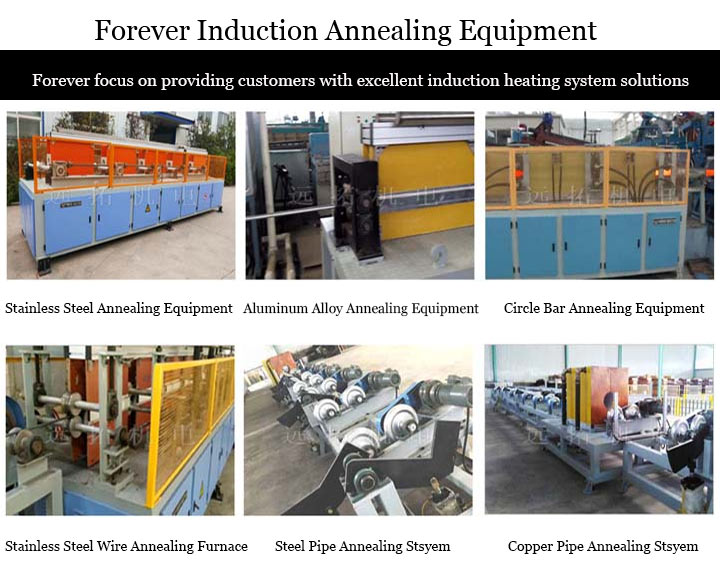

The Steel pipe induction annealing machine adopts a medium frequency heating device, which is specially designed by Forever Electromechanical for stainless steel annealing treatment. In response to the characteristic of heating the workpiece in motion as stainless steel, the entire stainless steel annealing equipment adopts a separate power supply for control. The stainless steel annealing equipment controlled by medium frequency induction power supply can achieve high-power regulation and low energy consumption!

The KGPs Medium frequency induction heating power supply control system adopts cutting-edge technology and excellent energy-saving effects. The control circuit of the entire stainless steel annealing equipment adopts a microcomputer constant power processing circuit system, and is equipped with an inverter angle automatic adjustment circuit function. The stainless steel automatically monitors the changes in voltage, current, and frequency during operation, and judges the changes in load based on this, and automatically adjusts the matching of load impedance, To achieve constant power output, thereby achieving the goal of saving time, electricity, and improving power factor.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)