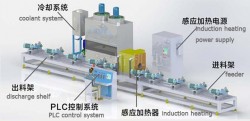

Steel Ball Forging Production Line

Features:

1. lower investment and faster development

2. have a larger range of steel ball production

3. have good impact resistance, strong toughness, good resistance

3. Forging can eliminate defects and optimize the microstructure

Product Detail

Application Video

Product Tags

Forever Furnace steel ball forging production line is non-standard product.The user need to tell us the steel ball diameter and production capacity,then we will give you the best offer and solutions.Also Forever Furnace can supply skew rolling machine, water cooling tank,steel ball quenching machine and so on.Welcome your inquiry!

Features of Forging Steel Ball Equipment

1.Automatic hardening temperature control with infrared thermometer to ensure hardening quality.

2.The roller has quick return function in case of roller stuck to avoid roller damage.

3.The red steel ball will be sent into forging mill to be rolled steel balls.The output quantity per minute is 40-120 balls each rolling mill.

4.The forged red steel balls will be sent into online heat treatment equipment for hardening-tempering to make the steel balls get high and uniform hardness.

Forever other large system for forging steel ball induction heating furnace

1.Round steel continuous heating production line with 500KW power

2.Grinding rod of 100mm diameter heat treatment system

3.Round steel continuous heating system with 2500KW power

4.PC steel bar heat treatment system

5.Long shaft automatic temperature control production line

6.Medium frequency hardening and tempering system

7.Steel ball hot forging production line of 2500KW power.

Forever furnace is engaged in forging steel ball equipment manufacturing for more than 16 years. If you are facing any problems about steel ball manufacturing, Forever Furnace will be very glad to help you as per our experience.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.