Seamless Steel Pipe Induction Annealing Machine

Features:

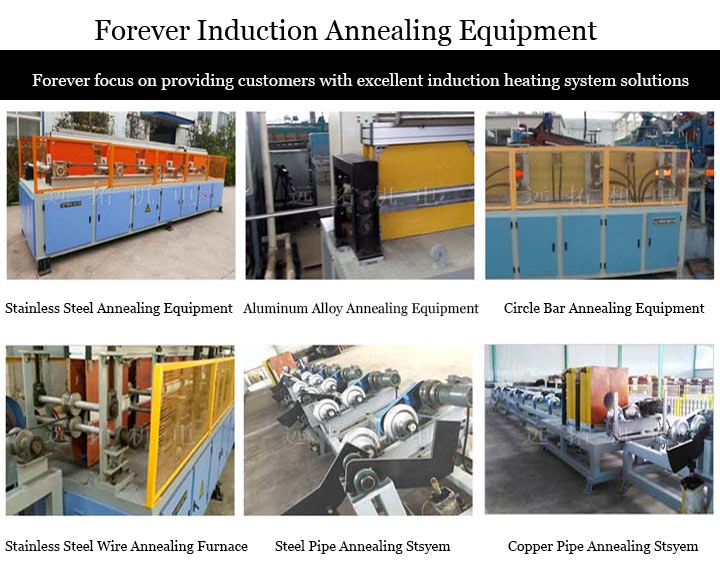

Seamless steel pipe induction heating annealing equipment is a non-standard product specially designed according to user requirements, mainly used in heat treatment workshops for steel pipes with diameters greater than 20mm, seamless steel pipes, stainless steel pipes, thick walled steel pipes, pipe billets, and other materials. Integrity, strength, and product quality have gained recognition from a wide range of users.

Product Detail

Application Video

Product Tags

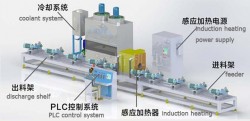

Hebei Yuantuo Electromechanical Equipment Manufacturing Co., Ltd. has a professional technical solution design team for steel pipe induction annealing system. We tailor a suitable seamless steel pipe induction annealing furnace according to your process requirements. The equipment is computer-controlled to achieve automatic feeding, heating, and unmanned operation throughout the entire process. The dual color American Raytheon infrared thermometer is used for stable real-time control of the steel pipe, with uniform heating and high product qualification rate.

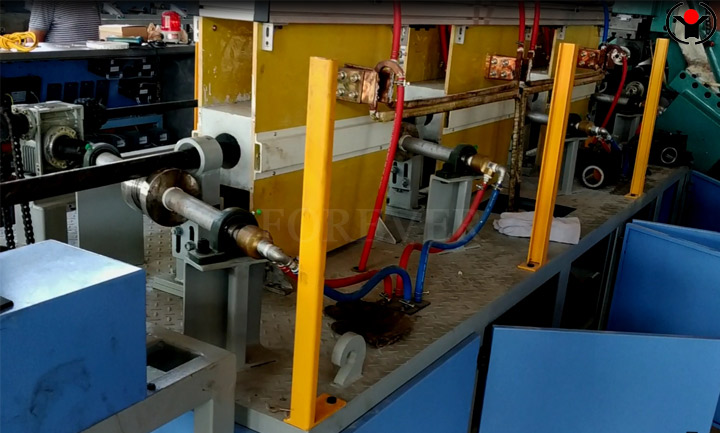

seamless steel tube annealing furnace

The parameter design of Forever Electromechanical Induction annealing steel pipe process requirements of users, and the manufacturing process follows a unified inductor manufacturing process: acid washing, drying, insulation treatment, casting; The pressure resistance reaches 1 megapascal per 10 minutes without leakage. The sensor base frame of the billet heating furnace is made of industrial aluminum alloy profiles, and the center height of the external dimensions is designed according to the workpiece, which can be fine tuned to meet the connection between the discharge and the connection of the billet on the entire loading and unloading line. The inductor of the Large steel pipe annealing system adopts a profile design, fully considering the factor of asymmetric cross-section of the product, and aligning with the direction of the press mold cross-section.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.