Hot Rolling Steel Ball Production Equipment

Features:

1.Induction heating power: DSP+IGBT ,Intelligent induction heating power.

2.Process monitoring screen and Data logging and Archiving.

3.Application:Special for steel ball production. Nonstandard and Customization Equipment

Product Detail

Application Video

Product Tags

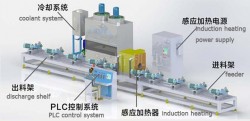

Hot Rolling Steel Ball Production Equipment for 20-150 mm steel balls

Established in 2004,Forever company is one of the technological innovation enterprises which involved in hot rolling steel ball production equipment.

The main production process of hot rolling steel ball production equipment as follows:

When hot rolling steel ball, the suitable steel bar to roll steel ball should be heat to 850 ~ 1100 DEG C first, then the heated steel bar was sent into skew rolling mill to roll.

(1) The round steel bar after the testing will be shear into a steel ball billet according to the length.

(2) The steel ball blank should be heated to the proper temperature in the continuous induction heating furnace before rolling.

(3) The reddest billet were fed into the skew rolling mill, rotate and move forward between the two rolls with special helical holes.Then the steel bars were rolled into balls continuously.

(4) The reddest ball finished rolling were entered online induction heat treatment equipment which our factory special designed immediately for hardening and tempering, so the steel ball to obtain very high and uniform hardness.

Common causes of failure and solutions for the hot rolling steel ball production equipment :

1. If no response from button on console and “Power on” light can’t be on, please check whether the main wire of 380 v three-phase has been connected or not.

2.If no response from button on console and “power on” light can’t be on , please check the 2P air breaker in the control cabinet.

3.If there is” ######” in the value box on the touch screen, and no response when you operate the screen, please check the wire connection between the touch screen and PLC is good or not .Also check whether the indicator lights of PLC modules turn to red or yellow.

4.If there is no response to the parameters of console meters and touch panel, please check whether you press the remote button , control switch and main switch on console ).

5.If the DC voltage, DC current on the console can’t continue to increase after pressing the “start” button , please check whether there is any fault in the power cabinet.

Forever company absorbed in providing customers with excellent solutions and service of induction heating system to make customers’ products more competitive.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.